Introduction to Industrial Adhesive Solutions

The Role of Industrial Adhesive Applications in Manufacturing

Industrial adhesive solutions play a crucial role in modern manufacturing, offering versatile bonding applications that are essential for a wide range of applications. Engineered to provide durable and reliable connections between materials, these adhesives reduce the need for mechanical fasteners such as screws and bolts. This shift towards adhesive technology has transformed manufacturing processes, resulting in lighter, more efficient, and aesthetically pleasing products.

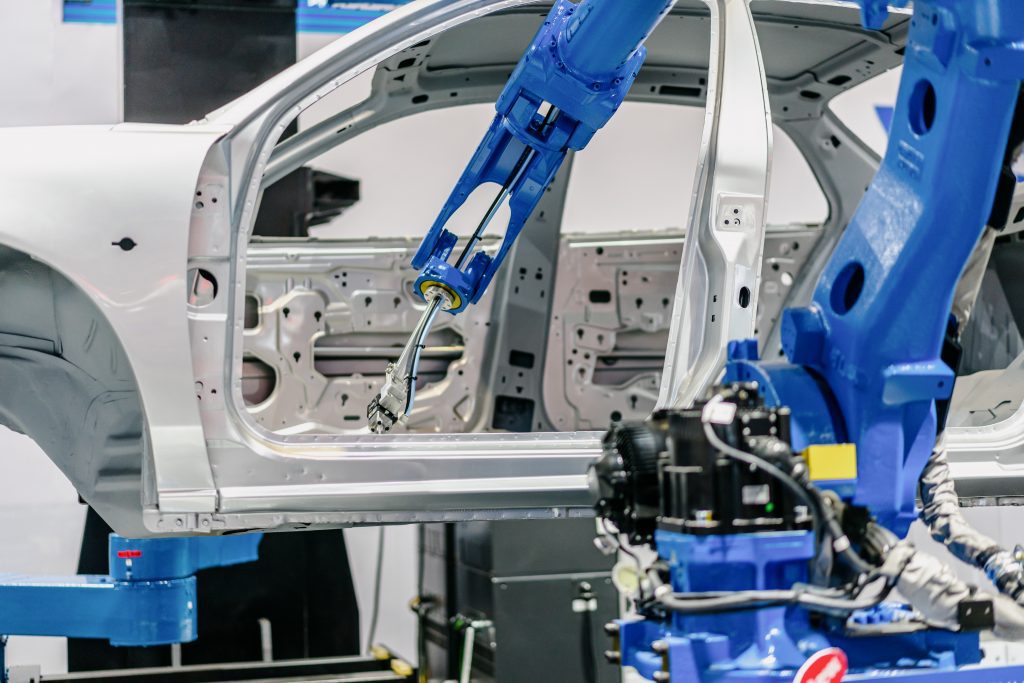

Manufacturing adhesives are tailored to meet the specific requirements of various industries. For example, in automotive manufacturing, industrial bonding materials are used to join metal, plastic, and composite components, enabling the creation of lighter vehicle structures without compromising strength or safety. Similarly, in the electronics industry, adhesives play a critical role in assembling intricate circuits and components, contributing to the miniaturization and flexibility of modern devices.

Advancements in adhesive technology have also helped the bonding of dissimilar materials, expanding the range of materials that manufacturers can use. This flexibility encourages innovation in design and reduces production costs by simplifying assembly processes. Industrial adhesives also support sustainability efforts by enabling easier disassembly and recycling at the end of a product’s lifecycle.

Advantages of Industrial Adhesive Solutions

Adhesive technology has become indispensable in the manufacturing sector, providing many advantages over traditional bonding techniques. The flexibility and versatility of industrial adhesives enable manufacturers to design intricate products while reducing expenses and enhancing performance.

One of the key benefits of industrial adhesive is its capacity to bond various materials such as metals, plastics, glass, and composites. This adaptability allows manufacturers to explore innovative designs without the constraints of conventional fasteners like screws and rivets. Industrial adhesives are particularly valuable in industries like automotive and aerospace where joining dissimilar materials is essential.

Industrial bonding agents distribute stress more uniformly across bonded areas, mitigating the risk of stress concentration and potential structural problems. This feature enhances the strength and longevity of products, ensuring their resilience in challenging conditions and harsh settings.

Additionally, adhesive technology contributes to weight reduction by dropping the need for heavy mechanical fasteners. This results in lighter products with enhanced fuel efficiency and reduced shipping expenses. Moreover, industrial adhesives streamline assembly processes, leading to quicker production times and lower labour costs.

Industrial adhesive solutions deliver a host of benefits including adaptability, strength, durability, and cost-effectiveness. These advantages have made them a preferred choice across various industries.

Types of Industrial Adhesive

Several types of industrial adhesives are available, each tailored for specific bonding applications. Cyanoacrylate adhesives, also known as “super glue,” are fast-setting and well-suited for precision bonding in electronics and medical device manufacturing.

Anaerobic adhesives, which cure without oxygen, are perfect for sealing and securing threaded components. Thread locking adhesives, a common type of anaerobic adhesive, prevent nuts and bolts from loosening due to vibrations.

Bearing retaining compounds, another type of anaerobic adhesive, are used to secure cylindrical components like bearings and shafts, offering high shear strength and resistance to temperature changes.

Structural adhesives are specifically designed for high-strength bonding in demanding applications such as automotive and aerospace industries. They can bond metals, plastics, and composites, ensuring structural integrity and reliability in various industrial settings.

Choosing the Right Industrial Adhesive

Considerations for Selecting Industrial Adhesives

Choosing the right industrial adhesive is essential for supporting the quality, efficiency, and reliability of manufacturing processes. It is important to consider key factors when selecting the right adhesive technology.

-

Material Compatibility:

Ensure that the industrial adhesive is compatible with the materials being joined to achieve best bonding.

-

Strength and Durability:

Consider the required strength and durability of the bond to decide the most suitable adhesive technology.

-

Cure Time and Process:

Evaluate the curing process and time needed for the adhesive, considering how it may affect manufacturing timelines.

-

Environmental Conditions:

Select an adhesive that can withstand the environmental conditions in which the bonded product will be used.

-

Application Method and Equipment:

Consider the application method and equipment needed for applying the adhesive to ensure compatibility with the manufacturing process.

-

Cost and Availability:

Consider the cost and availability of the adhesive to ensure a consistent supply and stay within budget.

By carefully considering these factors, manufacturers can choose the best industrial adhesive for their specific bonding needs, leading to improved product quality, efficiency, and reliability.

The automotive industry uses adhesives, to reduce weight during manufacturing.

Applications of Industrial Adhesives

Industrial adhesives play a crucial role in various industries due to their versatility and advancements in technology. They are essential in modern manufacturing processes, offering innovative bonding solutions and enhancing product efficiency. Here are some key applications of industrial adhesives:

-

Automotive Industry:

Industrial adhesives are extensively used in vehicle part assembly, reducing the need for heavy mechanical fasteners and leading to lighter vehicles with improved fuel efficiency. They also aid in noise reduction and vibration damping, enhancing overall vehicle comfort.

-

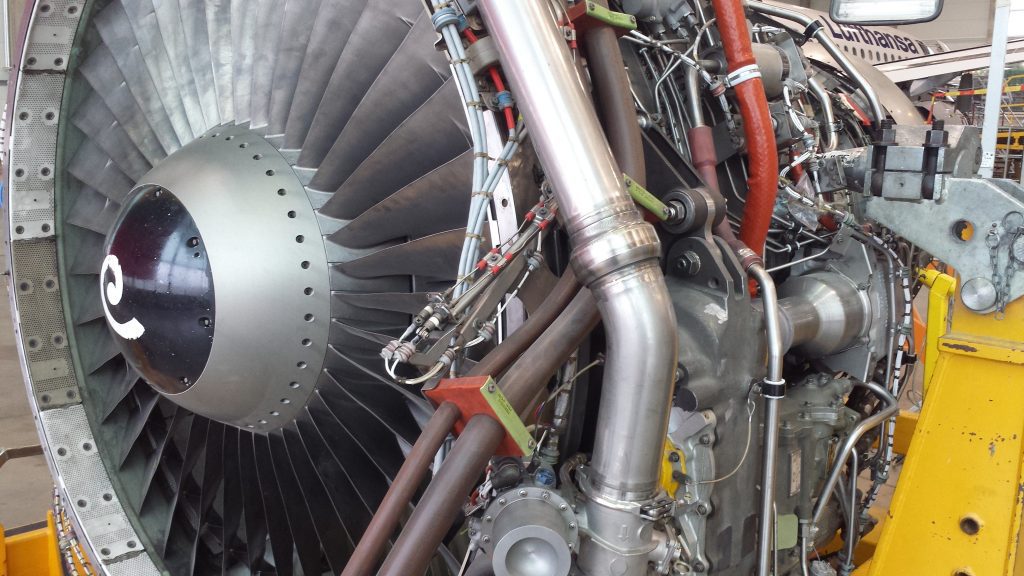

Aerospace Sector:

High-strength industrial adhesives are vital in bonding structural components in aerospace applications, ensuring the safety and integrity of aircraft. They enable lighter aircraft designs, contributing to fuel savings and longer flight ranges.

-

Electronics Manufacturing:

Adhesive technology is essential for assembling circuit boards, bonding components, and securing wires in the electronics industry. Industrial adhesives with high thermal conductivity help dissipate heat, ensuring the longevity of electronic devices. They also ease miniaturization and compact designs.

-

Construction Industry:

Industrial adhesives are widely used in construction for bonding materials like wood, concrete, and glass. They provide durable connections for architectural components, enabling innovative designs and reducing construction times. These adhesives are also used in insulation and waterproofing applications.

-

Medical Sector:

Industrial bonding materials are crucial in creating reliable connections in medical devices and equipment, meeting strict regulatory requirements, and providing biocompatible solutions. They are used in the assembly of catheters, syringes, and surgical instruments.

Industrial adhesives offer diverse applications across industries, providing durable, efficient, and innovative bonding solutions. Their adaptability and strength make them a vital part in modern manufacturing processes.

Electronics industry, adhesives for bonding electrical products to enhance manufacturing efficiency.

Understanding Adhesive Technology

Innovations in Industrial Bonding Materials

Recent years have brought significant advancements in industrial bonding materials, fuelled by the demand for stronger, more efficient, and eco-friendly adhesive technology. These innovations in industrial adhesive products have opened new possibilities for bonding solutions, revolutionizing manufacturing processes and expanding the scope of applications for these products.

One area of notable progress is the development of high-performance structural adhesives. These adhesives boast exceptional strength and durability, making them well-suited for demanding applications in industries like aerospace, automotive, and construction. Modern structural adhesives can effectively bond dissimilar materials, enhancing design flexibility for manufacturers.

Another noteworthy development is the creation of low-odour cyanoacrylate adhesives. These environmentally friendly adhesives are formulated to minimize their impact on both workers and the environment. Unlike traditional cyanoacrylate adhesives that emit strong fumes, low-odour variants reduce fumes, promoting a more pleasant work environment. By addressing concerns related to strong odours, these adhesive innovations align with the industry’s focus on user comfort.

Advancements in adhesive technology have also led to improvements in cure times and application methods. The introduction of quick-curing industrial adhesives has resulted in increased production efficiency by minimizing downtime. Additionally, new application techniques, such as automated dispensing systems, enable precise and consistent adhesive application, enhancing product quality and reducing waste.

The aerospace industry would commonly use anaerobic adhesives and structural acrylics for weight reduction and bond strength.

Best Practices for Applying Industrial Adhesives

Proper application of industrial adhesives is essential for creating durable bonds and keeping best manufacturing standards. Below are some recommended practices for effectively using industrial glue:

-

Surface Preparation:

Begin by thoroughly cleaning surfaces to remove dirt, grease, and other contaminants that could affect adhesion. In some cases, lightly sanding or roughening the surfaces can improve bonding.

-

Adhesive Selection:

Choose industrial adhesives that are compatible with the materials being bonded, offer the required strength, and can withstand environmental conditions. Select an adhesive that meets these criteria to ensure a dependable bond.

-

Application Quantity:

Apply the right amount of industrial glue to avoid excessive squeeze-out or weak bonds. Adhere to the manufacturer’s instructions for quantity and application technique.

-

Even Distribution:

Ensure the adhesive is evenly spread across the bonding surface to prevent weak spots and premature failure. Utilize tools designed for uniform application for consistent results.

-

Curing Process:

Follow the recommended curing times and conditions for the adhesive being used. Some adhesives may require specific temperatures, humidity levels, or pressure for proper curing. Adhere to guidelines to achieve a strong bond.

-

Safety Measures:

Prioritize safety by wearing protective gear, such as gloves and safety goggles, and keeping adequate ventilation to avoid inhaling fumes when handling industrial bonding materials.

By following these best practices, manufacturers can set up reliable bonding solutions that uphold product quality and safety throughout the manufacturing process.

Conclusion

Industrial adhesives are vital in modern manufacturing, offering effective bonding solutions that drive innovation and productivity across multiple industries like automotive, aerospace, and electronics. These materials bond different materials, enhance durability, and reduce production costs. Advancements in adhesive technology have led to innovations like high-performance structural adhesives, low-odour cyanoacrylate adhesives, and environmentally friendly options for a cleaner and safer work environment.

Choosing the right industrial adhesive involves considering material compatibility, strength requirements, curing methods, environmental factors, and costs. Automated application methods and smart adhesives with sensors are enhancing industrial bonding solutions for better quality and efficiency. Following best practices for adhesive application is crucial for creating strong and durable bonds, ensuring product safety and longevity. Proper surface preparation, consistent application, and safety compliance are essential for reliable results.

In summary, industrial adhesives are a fundamental element of contemporary manufacturing operations, offering durable, efficient, and environmentally conscious bonding solutions. As adhesive technology progresses, manufacturers can predict increased flexibility and sustainability in their bonding processes, enabling them to stay at the forefront of innovation and excellence.

Our Industrial Adhesive Brands

Acquire Cyanoacrylate Products from our Procure® range, such as adhesive grades, activators, primer, debonder, and dispensing nozzles.

Utilize the Mitrelock® Mitre Adhesive Kit for efficient bonding of wood with minimal edge lifting.

Choose REACT GP for construction, plastics, and window fitting, featuring a low stain activator for UPVC.

Explore Lockfast® Engineering Adhesives, which we acquired in 2010 and include anaerobic engineering adhesives, structural acrylics, and epoxies.

Discover Procure® UV Adhesives, which offer optically clear light-curing adhesives for a variety of applications.

To view our complete product range, please Click here.

Adhesive Supplier

Adhesive Supplier